Sack Making Machine Square Bottom PP Woven Wheat Flour Bag Make Machines

Basic Info

| Model NO. | WSA |

| Lines | 1 |

| Voltage | 380V |

| Seals Mode | Ultrasonic Sealing |

| Speed | High |

| Continuous-Rolled | Yes |

| Sealing & Cutting | Heat-Sealing Cold-Cutting |

| Layer | Single |

| Machine Type | Bag Forming Machine |

| Computerized | Computerized |

| Type | PP Woven Sack Making Machine |

| Certification | CE, SGS, ISO9001 |

| Applicable Industries | Cement, Resin, and Other Bulk Material |

| Marketing Type | New Product 2022 |

| Installation | Door-to-Door Service |

| Video Outgoing-Inspection | Provided |

| Core Components | Motor, PLC |

| Condition | New |

| Key Selling Points | Independent Patented Technology |

| Machinery Test Report | Provided |

| Max Speed | 120PCS/Min |

| Color | Gray, Blue, or Customized |

| Machine Power | 105kVA |

| Web Tension Control | Automatic |

| Sack Width | 300-600mm |

| Sack Length | 410-910mm |

| Transport Package | Plastic Film and Wooden Box Package |

| Specification | 12000*7500*3000mm |

| Trademark | Allwell |

| Origin | China |

| HS Code | 84778000 |

| Production Capacity | 20 Sets/Month |

Product Description

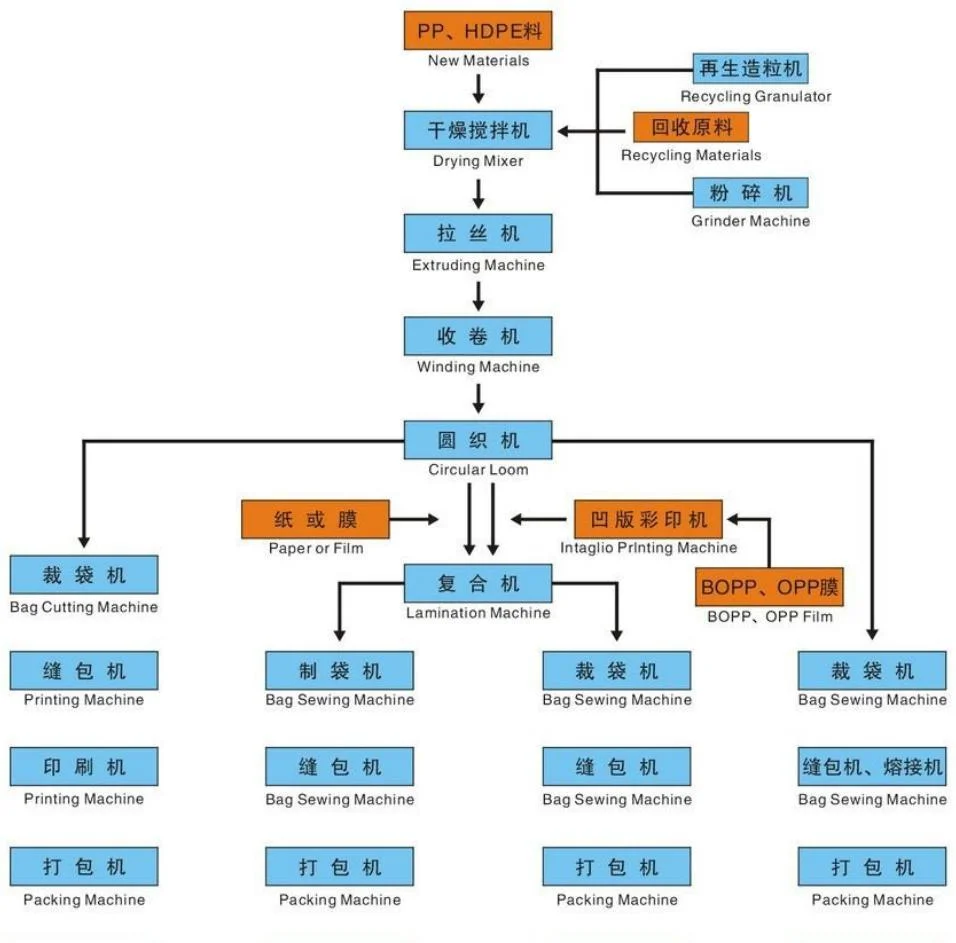

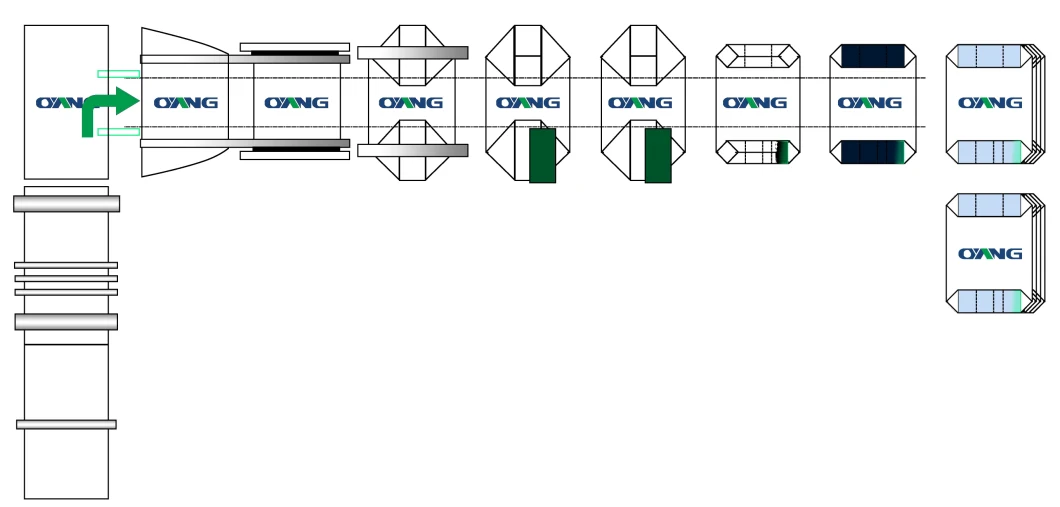

ON-WSA Block Bottom Valve Sack Making Machine

Minimize space for storage and during transportation process, combined with valve for easy filling, especially for cement industry that is commonly using rotary packer to maximize their filling capacity. It is also stronger and more durable than multi-ply kraft paper or pp woven sandwiched kraft paper cement bag. Suitable: Block bottom PP woven valve bag, widely used for cement, resin, and other bulk material.

Product Parameters

| 1. Technical Parameter | |

| Sack width | 300-600 mm |

| Sack length | 410-910 mm |

| Bottom width(B > 160 mm | 80-180 mm |

| Bottom center distance | 310-680 mm |

| Main fabric cutting length | 510-1090 mm |

| Fabric width | 55-80 g/m² |

| Coating Weight(15% PE, 85% PP) | 17-30 g/m² |

| Speed | 90-120 bags/min |

| 2. Material Specification | |

| 2.1 Tubular fabric requirement | |

| Material specification | 2.5-5 mm PP tapes |

| Fabric Weight | 55-80 g/m² |

| Coating Weight | 17-30 g/m² |

| Coating adhesion | Min. 8.1N/30mm |

| Width tolerance | ±7 mm |

| Weight tolerance (fabric + coating) | ±3 g/m² |

| Over coating | Max. 5mm |

| 2.2 Flat fabric for patches | |

| Fabric Weight | 55-80 g/m² |

| Coating Weight(15% PE, 85% PP) | 17-30 g/m² |

| Coating adhesion | Min. 8.1N/30mm |

| Width tolerance | ±3 mm |

| Weight tolerance (fabric + coating) | ±3 g/m² |

| 3. Electrical,water,air requirement | |

| Power | 105 KVA |

| Water consumption(Max 18°C, 4 bar) | 2m³/h |

| Operating pressure | 6-7 bar |

| Air consumption | 120 m³/h |

| Air compressor | Prepared by customer |

| 4. Space requirements | |

| Equipment Size | L*W*H: 12 m×7.5 m×3m |

| Ground strength | The installation place must keep the ground flat and have enough bearing pressure. The foundation should not conduct vibrations generated during operation. The permissible ground load must not be lower than 25000 N/m2. |

| Environment temperature | The equipment should not be installed outdoors! The ambient temperature in production halls and warehouses must be between 18 °C and 40 °C! |

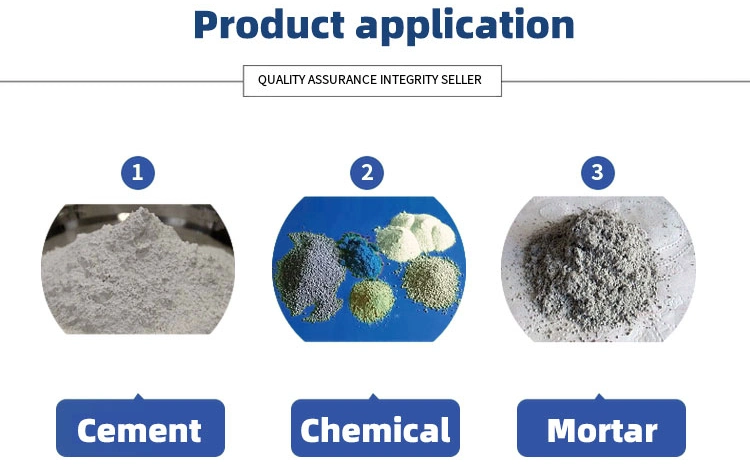

Production Process

PP Woven Bag Making Machines with Capacity 30 million Bags/Year

Company Profile

FAQ

Q1. How long will your engineer reach our factory?Our After-sales Specialist would contact you to confirm the final scheduling according to your reasonable request.Q2. How many days will you finish installing?We will finish installation and training within 1-2 weeks.Q3. What should we charge for your engineer?You should charge for the cost of our engineer's visa, air tickets,SIM card, hotel, food, and also their salary 150USD one day per person.Q4. How long is your machine's warranty period?All our machine have one year guarantee, starting from finished installation.

Q5. How could we do if the parts broken within warranty?We would express the free replacement parts during the warranty date.Q6. Does your engineer speak English?Our engineers understand a little English. All of our engineers have more than five years machine installation experience.

Q7. How do we solve the machine problem after your engineer leaving?Generally speaking, there will be no problem after finish installing. In case any problem, you can contact our after sales specialist at any time. There are 30 engineers at our after-sales department with 30 engineers and they'll take solution videos according your description.